Quay Crane Wire Rope Automatic Real-Time Online Inspection System

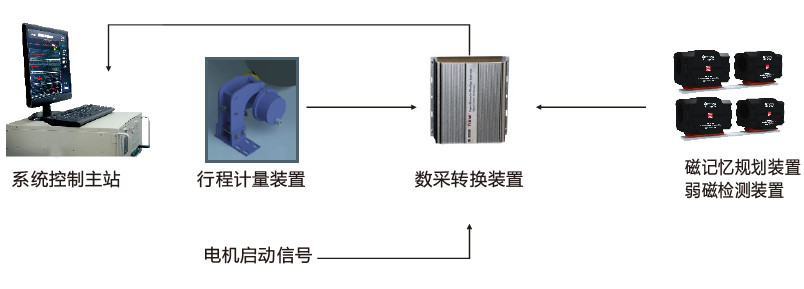

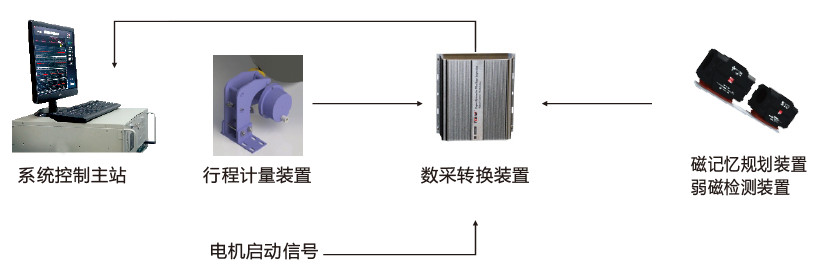

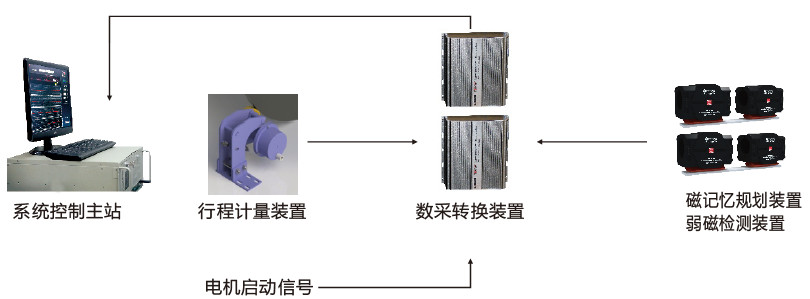

1. System Configuration

Unique Advantages:

- 1. Wire rope whole service life under safety control

- 2. Synchronized inspection during high-speed operation

- 3. Replacing manual inspection with machine visual identification inspection

- 4. Integration of MRT & VI system.

- 5. Internet + expert inspection with remote diagnosis

Inspection accuracy:

- ● Severe Flaw Value: Real-time Detection rate: 100%

- ● Serious Flaw Value: Real-time Detection rate: 100%

- ● Medium Flaw Value:Real time Detection rate: 99%

- ● Slight Flaw Value: Real-time Detection rate: 90%

- ● Minor flaw:Real-time detection rate>80%

Conforming to:

- ● Standard practice for electromagnetic examination of ferromagnetic steel wire rope (ASTM-E1571-2011)

2. Technical parameters:

1.LF/LMA equivalent repeatability: <±1%

2.Statistical uncertainty for number of broken wires in the length of 6D and 30D(visual identification device optional): <1

3.Measuring tolerance of wire rope diameter(visual identification device optional): <±1%

4.Rope speed for inspection: 0-4m/s Rope speed for monitoring: 0-15m/s

5.Flaw positioning accuracy: ≥99%

6.Inspection range of wire rope: Φ26-76mm

7.Sensor working temperature: -20℃~55℃Humidity: ≤95%RH

8.Ingress Protection: IP67

Replacing Manual Inspection with Machine Intelligence

TCK.W, Winner of OTC 2018 Innovation Award

TCK.W Automatic Real-time Online Wire Rope Inspection System will revolutionize periodic human visual inspection and bring in-process safety monitoring to its highest state through continuous inspection during operation.

“We can never forget that its companies like the 2018 Spotlight Award winners that are driving the technological advancements necessary to propel our industry for the next 50 years.”—Paul Jones Spotlight Award Committee Chair

24HOURS X 365DAYS WIRE ROPE FULL LIFE CYCLE SAFETY MANAGEMENT

COMPLETELY SOLVE THREE KEY PROBLEMS OF WIRE ROPE: HIDDEN DANGER, WASTE, LOW EFFICIENCY, AND REALIZE THREE MANAGEMENT OBJECTIVES NAMELY SAFETY, ECONOMY,AND HIGH EFFICIENCY

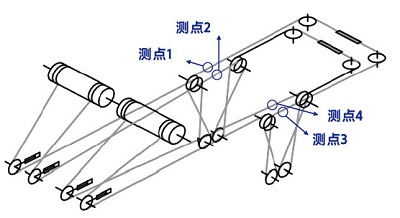

Hoist Rope Inspection System

|

|

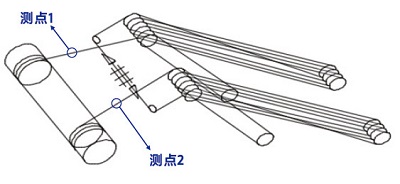

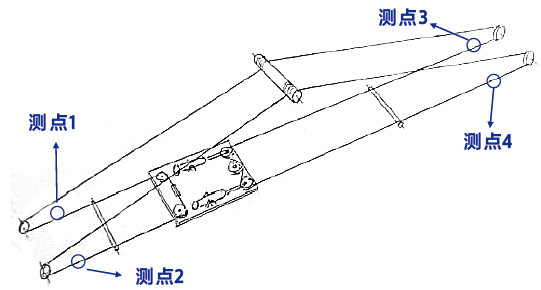

Boom rope inspection system

|

|

Trolley Rope Inspection system

|

|

3. Test report

4. Application In-Situ

Field case

Field case